You’ve just pulled into your driveway after a long drive, and you remember—it’s time to check your engine oil. The question hits you: Can I check my oil when the engine is hot? This seemingly simple maintenance task sparks confusion for countless car owners who want accurate readings without compromising safety.

Engine oil checks are an essential part of keeping your vehicle in good shape. You need reliable measurements to avoid underfilling (which can cause serious damage to your engine) or overfilling (which can lead to foaming and reduced lubrication efficiency). The temperature of your engine directly affects what you see on that dipstick.

Here’s what you need to know: checking your oil immediately after shutting down a hot engine won’t give you the most accurate reading. The sweet spot? Wait 5–10 minutes after running the engine. This brief cooling period allows oil to drain back into the sump while still reflecting your engine’s operating conditions—giving you the balance between measurement accuracy and personal safety you’re looking for.

- Understanding Engine Oil’s Role and Importance

- The Science Behind Hot vs Cold Oil Level Readings

- Manufacturer Guidelines: Hot or Cold Checks?

- Pros and Cons of Checking Engine Oil When Hot

- Pros and Cons of Checking Engine Oil When Cold or After Cooling Period

- Best Practices for Accurate Engine Oil Level Measurement

- Special Considerations for Diesel Engines and Hot Climates

- Common Issues Explained: Why Oil Level May Appear Too High When Checked Hot?

- How to Interpret Dipstick Readings After Running The Engine

- Conclusion

- FAQs (Frequently Asked Questions)

Understanding Engine Oil’s Role and Importance

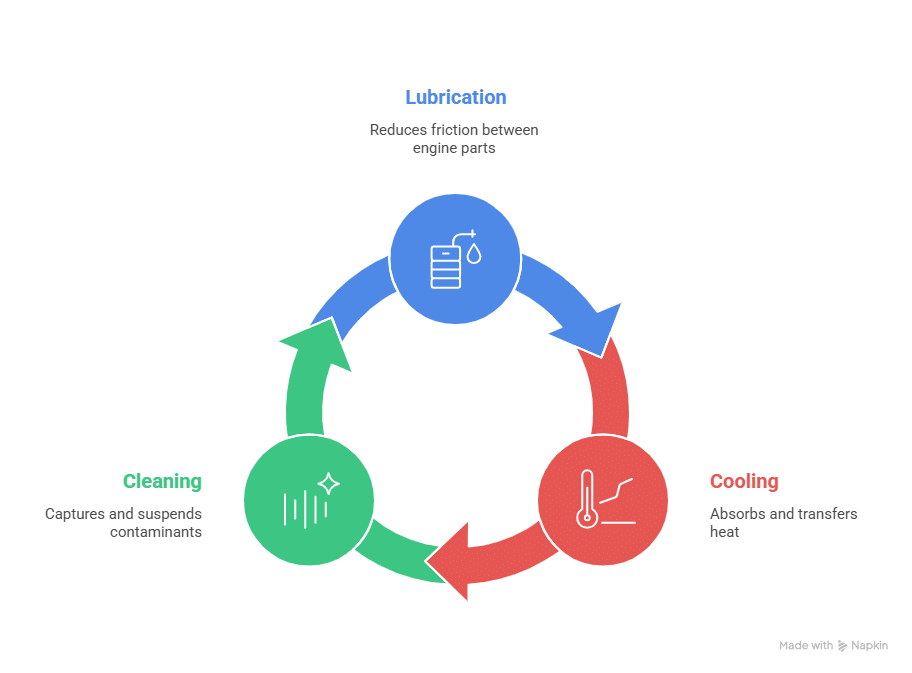

Engine oil is essential for your vehicle, performing three critical functions that keep your engine running smoothly:

- Lubrication: Engine oil prevents metal parts from rubbing against each other, reducing friction and wear on components like pistons, crankshafts, and camshafts.

- Cooling: The oil absorbs heat from engine parts and transfers it away from areas where combustion temperatures can exceed 2,000°F, acting as a cooling agent.

- Cleaning: Engine oil captures dirt, metal particles, and combustion byproducts, suspending these contaminants until your next oil change.

The Impact of Engine Oil Level on Performance

The level of engine oil in your vehicle directly affects its performance. Here’s how:

- Insufficient Oil: Running with low oil levels means that moving parts won’t get enough lubrication. This can lead to increased friction, overheating, and even severe engine damage.

- Overfilled Oil: On the other hand, too much oil can create problems of its own. The crankshaft may whip excess oil into foam, reducing its ability to lubricate and potentially causing oil leaks through seals and gaskets.

How Oil Condition Affects Your Engine

The condition of your engine oil also plays a role in how accurately you can read its level. When checking your oil level, it’s important to remember that:

- Hot Oil vs. Cold Oil: Oil viscosity changes with temperature—hot oil becomes thinner and flows differently than cold oil. This means that if you’re checking your oil when the engine is hot, the reading may not be accurate.

- Contaminated Oil: If your engine oil is contaminated with fuel or coolant, it can affect both the volume and behavior of the oil. This is especially critical for diesel engines where higher operating temperatures and different viscosity requirements come into play.

By understanding these factors—engine oil’s functions, the impact of its level on performance, and how its condition affects readings—you can better maintain your vehicle’s engine health.

The Science Behind Hot vs Cold Oil Level Readings

When you check oil level hot vs cold, you’re dealing with fundamental physics that directly impacts measurement accuracy.

1. Thermal Expansion of Oil

The thermal expansion of oil means your engine oil increases in volume by approximately 3-5% when heated from room temperature to operating conditions (around 200°F or 93°C). This expansion can make your dipstick show a higher reading immediately after shutdown, potentially leading you to believe you have more oil than you actually do.

2. Viscosity Changes Hot vs Cold

The viscosity changes hot vs cold present another measurement challenge. Hot oil becomes significantly thinner—its viscosity drops dramatically as temperature rises. This thinning allows oil to flow more freely through your engine’s passages and galleries. When you shut off your engine, this thin, hot oil needs time to drain from various components back into the oil pan where your dipstick measures it.

3. Oil Drainage Time

Oil drainage time is the critical factor most car owners overlook. After you turn off your engine, oil continues trickling down from:

- Cylinder heads and valve covers

- Oil galleries and passages

- Turbocharger bearings (if equipped)

- Oil filter housing

- Timing chain or belt tensioners

This drainage process typically takes 5-10 minutes. If you check immediately after shutdown, you’re measuring only the oil that’s already settled in the pan—not the total oil capacity. This incomplete drainage creates artificially low readings that might prompt you to add oil when you don’t actually need it. To avoid such miscalculations, it’s advisable to wait for a period before checking your oil level, ideally around 5-10 minutes after turning off the engine for more accurate results.

Manufacturer Guidelines: Hot or Cold Checks?

When you look at your owner’s manual, you’ll see that different brands and models have their own instructions for checking oil. Some car manufacturers say to check the oil when the engine is completely cold—usually before you start driving for the day. Others want you to check it when the engine is warm, after running the vehicle until it reaches its normal operating temperature.

Toyota and Honda, for example, usually recommend cold checks for most of their models, while BMW and Mercedes-Benz often say to check the oil after the engine has warmed up and then cooled down for 5-10 minutes. Ford suggests either checking when it’s cold or after a short cooling period following warm-up.

The differences come from various factors like engine designs, oil pan shapes, and dipstick placements. Some engines have deeper oil sumps where the oil takes longer to settle, while others have baffled pans that affect how the oil drains.

You must follow your specific vehicle’s instructions because dipstick markings are based on these manufacturer-specified conditions. If you use the wrong method, you could misread your actual oil level by as much as half a quart—enough to cause worry or unnecessary top-ups.

Pros and Cons of Checking Engine Oil When Hot

When you check your oil with a hot engine, you’re measuring the level under conditions that closely mirror actual driving. This approach reveals the realistic ‘in-use’ oil volume your engine operates with, which can be valuable for understanding how your vehicle performs during normal operation.

Benefits of Checking Hot Engine Oil

Checking hot engine oil benefits include:

- Assessment of oil level at operating temperature

- Detection of consumption patterns during active use

- Immediate feedback after a drive when concerns arise

Risks of Checking Hot Engine Oil

The risks of checking hot engine oil present serious challenges:

- Oil hasn’t fully drained back to the sump, creating artificially low readings that may prompt unnecessary topping up

- Severe burn hazards from contact with hot engine components, oil cap, or dipstick handle

- Steam or hot oil vapor can cause injury during inspection

- Thermal expansion may show higher levels than actual cold volume, leading to potential overfilling if you add oil based on this reading

You need to weigh these factors against your specific situation and manufacturer recommendations before deciding when to perform your oil check.

Pros and Cons of Checking Engine Oil When Cold or After Cooling Period

Benefits of Checking Cold Engine Oil

Checking cold engine oil benefits center around measurement stability and safety. When you allow your engine to cool for 5–10 minutes after shutdown, the oil has sufficient time to drain completely back into the pan. This settling period gives you the most accurate representation of your total oil volume, eliminating the guesswork caused by oil still clinging to engine components.

The advantages of this approach include:

- Stable, consistent readings – All oil has returned to the sump

- Reduced burn risk – Engine surfaces have cooled enough to handle safely

- Easier comparison over time – Checking under similar conditions creates reliable baseline measurements

Trade-Offs in Accuracy: Cold vs Hot Oil Check

Cold vs hot oil check accuracy reveals some trade-offs. In extremely cold ambient temperatures, oil viscosity increases significantly, which can make the oil appear thicker on your dipstick than during normal operation. This viscosity change means your cold reading might differ slightly from the actual operating volume your engine experiences at full temperature. You’re getting an accurate measurement of what’s in the pan, but it may not perfectly reflect the oil’s behavior when your engine reaches its working temperature range.

Best Practices for Accurate Engine Oil Level Measurement

The best time to check engine oil strikes a balance between operating temperature and safety. You should run your engine until it reaches normal operating temperature, then shut it off and wait 5–10 minutes before checking. This dwell period allows the oil to drain back into the sump while remaining warm enough to reflect realistic operating conditions.

How to check engine oil properly

How to check engine oil properly requires attention to your vehicle’s position and technique:

- Park on level ground – even a slight incline can skew your reading by several millimeters on the dipstick

- Locate the dipstick and pull it out completely

- Wipe it clean with a lint-free cloth or paper towel

- Reinsert the dipstick fully until it seats properly in the tube

- Withdraw it slowly and hold it horizontally to prevent oil from running

When you read the dipstick after an engine run, examine where the oil film sits between the minimum and maximum marks. The oil should leave a clear, consistent line across the dipstick blade. If you’re performing an Engine Oil Check when Hot, you need to be cautious around heated components – use gloves or a cloth to protect your hands from burns.

Consistency matters more than the specific method you choose. You should always check your oil under the same conditions (same temperature state, same dwell time) to track changes accurately over time.

Special Considerations for Diesel Engines and Hot Climates

Diesel engines present distinct challenges when performing a diesel engine oil check hot conditions. These powerplants operate at significantly higher temperatures than gasoline engines, often reaching 220-250°F in the oil pan. The oil itself typically has different viscosity characteristics—diesel engines commonly use 15W-40 or 5W-40 grades that behave differently under heat stress.

When checking diesel engine oil after running, you need to extend your cooling period to 15-20 minutes rather than the standard 5-10 minutes. The larger oil capacity in most diesel engines (often 10-15 quarts versus 4-6 quarts in gas engines) means more time for complete drainage back to the sump.

Also Read: Why Is There Oil On Spark Plugs? Causes and How to Fix It

In hot climates where ambient temperatures exceed 95°F, the cooling process slows dramatically. You’ll face two compounding factors: the engine’s residual heat and the environmental heat preventing efficient cooling. Consider these strategies:

- Check oil early morning before the day heats up

- Park in shaded areas when possible before checking

- Wear heat-resistant gloves when handling the dipstick

- Allow 20-30 minutes of cooling time in extreme heat (100°F+)

- Keep a thermometer gun handy to verify surface temperatures below 150°F before touching engine components

Moreover, it’s crucial to understand that the viscosity of diesel engine oils can change significantly with temperature, which further complicates the oil checking process in hot conditions.

Common Issues Explained: Why Oil Level May Appear Too High When Checked Hot?

You might notice a high oil level reading hot engine scenario when checking your dipstick immediately after shutdown. This happens because engine oil undergoes thermal expansion during operation—the molecules spread apart as they heat up, increasing the oil’s total volume by approximately 3-5% at operating temperature.

When you check your oil within seconds or a minute of turning off the engine, you’re measuring this expanded volume. The dipstick shows a reading that suggests you have more oil than you actually do when the engine is cold. This creates a dangerous situation: if you base your oil top-up decisions on this inflated reading, you risk overfilling your engine once the oil cools and contracts back to its normal volume.

The problem compounds because hot oil hasn’t fully drained from the cylinder head, valve covers, and oil galleries back into the sump yet. You’re getting a false high reading from both thermal expansion and incomplete oil return. Oil level too high when checked hot — why? The answer lies in physics: you’re measuring a temporary state rather than the true resting volume of your oil supply.

How to Interpret Dipstick Readings After Running The Engine

When you perform an Engine Oil Check when Hot, understanding your dipstick reading guide after running the engine becomes critical for accurate interpretation. The timing of your measurement directly impacts what you see on that dipstick.

Immediate readings (within 1-2 minutes of shutdown) typically show lower levels because oil hasn’t fully drained from upper engine components back into the pan. It’s advisable to wait for a period before checking, as suggested in this discussion about how long an engine should be off until checking the oil level. After waiting 5-10 minutes, you’ll notice the level rises as gravity does its work. This fluctuation is normal—not a sign of something wrong with your engine.

Your dipstick features two distinct marks:

- MIN (or Lower Mark): The absolute minimum safe operating level. Running below this risks inadequate lubrication and potential engine damage

- MAX (or Upper Mark): The maximum recommended fill level. Exceeding this can cause foaming, increased pressure, and seal damage

The ideal reading sits between these marks, typically in the upper half of the range. You want to see a clear oil film coating the dipstick between MIN and MAX.

It’s important to understand what these markings mean, which you can read more about in this informative post about oil dipstick markings.

Reading consistency matters. If you check oil after a 10-minute wait on Monday, do the same on Friday. However, be cautious of external factors like extremely cold weather which can impact dipstick readings, leading to apples-to-oranges data that won’t help you track actual consumption or detect leaks. Keep your checking conditions similar—same temperature state, same wait time, same level ground—to spot genuine changes in your oil level over time.

Conclusion

Regular engine oil checks are your best defense against expensive repairs and unexpected breakdowns. Don’t rely only on service interval warnings or dashboard indicators—they can’t detect every leak or consumption problem before damage happens.

Your action plan for reliable engine oil checks:

- Run your engine to normal operating temperature

- Wait 5–10 minutes after shutdown for oil to settle

- Park on level ground before checking

- Follow your manufacturer’s specific guidelines

- Check consistently under the same conditions

The question “Can I check my oil when the engine is hot?” has a nuanced answer: yes, but with proper timing and technique. You need that brief cooling period to balance measurement accuracy with realistic operating conditions.

Start implementing these practices today. Make engine oil checks part of your monthly routine, not just something you do when warning lights appear. You’ll catch problems early, extend your engine’s lifespan, and drive with confidence knowing your lubrication system is properly maintained. Your engine—and your wallet—will thank you.

FAQs (Frequently Asked Questions)

Yes, you can check your engine oil when the engine is hot, but it’s recommended to wait for a short period after running the engine. This allows oil to drain back into the sump, providing a balance between safety and measurement accuracy.

Thermal expansion causes engine oil to increase in volume as temperature rises. Checking oil immediately after shutdown can show an inflated level due to this expansion, potentially leading to inaccurate readings and overfilling risks.

Checking oil when hot gives a realistic ‘in-use’ level assessment close to operating temperature but risks burn hazards and incomplete draining. Checking when cold or after a short cooling period offers stable readings with fully settled oil but may slightly differ from operating volume due to viscosity changes.

For accurate measurement, run the engine until it reaches normal operating temperature, then wait 5–10 minutes before checking. Ensure the vehicle is on level ground, wipe the dipstick clean, fully reinsert it, withdraw slowly, and read between the minimum and maximum marks.

Yes. Diesel engines operate at higher temperatures with different viscosity requirements, making checks more sensitive. In extremely hot climates, ambient temperatures affect cooling time, so allow adequate cooling before checking to ensure safety and accuracy.

Engine oil lubricates, cools, and cleans engine components. Both low and high oil levels can cause performance issues and damage. Maintaining good oil condition—including proper viscosity and minimal contamination—is essential for accurate level readings and optimal engine health.